Did you know that keeping foods in the temperature danger zone of 41 to 135 °F (5 to 57 °C) is known as time-temperature abuse, which is a common source of foodborne illness and a major health code violation?

TCS, which stands for Time/Temperature Control for Safety, is considered to be time and temperature abused at any time when they are exposed to a temperature danger zone. Food safety software and quality management systems incorporating tech-enabled integrated monitoring solutions for real-time supervision of TCS foods present a whole new level of efficiency and precision in food preservation processes and ensure food safety.

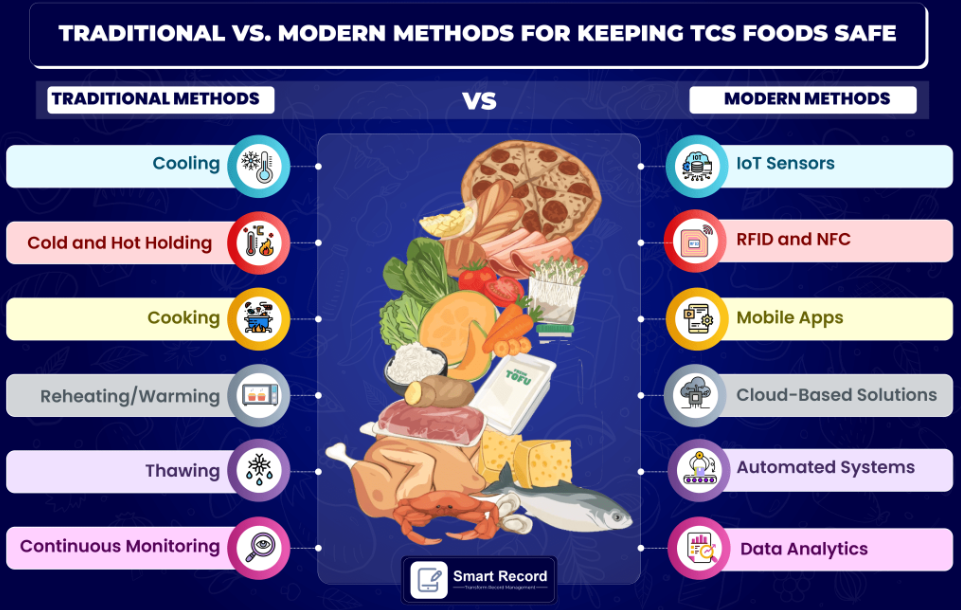

Traditional Methods

Traditional methods of controlling food time and temperature conditions often depend on manual processes and conventional cooking equipment, such as stovetops, ovens, and grills.

Cooling

Cooling is the rapid reduction of hot cooked food temperatures from 140°F/60°C to 41°F/5°C or lower within 2 hours to minimize the "danger zone."

Thawing

Thawing is the process of safely defrosting frozen food, preferably in a refrigerator at 40°F (4°C), to prevent the reactivation of pathogens.

Cold- and Hot-Holding

Cold-holding involves keeping perishable food below 41°F/5°C to prevent bacterial growth, typically in refrigerators or cold-holding units. Hot-holding maintains hot food at 135°F/57°C or higher to inhibit bacterial growth, often using equipment like steam tables or chafing dishes.

Reheating/Warming

Reheating warms precooked food to a safe serving temperature of 165°F/74°C, ensuring uniform heat distribution to eliminate potential bacterial contamination.

Cooking

Cooking is the process of preparing food by applying heat to kill harmful bacteria and pathogens and make the food safe to eat through grilling, roasting, frying, boiling, and baking.

Continuous Temperature Monitoring

Continuous temperature monitoring ensures food stays within safe temperature ranges during all stages of handling and storage to prevent foodborne illnesses.

Modern Methods

In contrast, modern methods leverage advanced food safety technology, such as sous-vide cooking machines, precision ovens, and refrigeration systems with digital controls. These technologies enable precise and consistent temperature and time management.

IoT Sensors

Internet of Things (IoT) sensors are used to monitor temperature and humidity in real-time. These sensors are often connected to a central control system via the Internet, allowing for remote monitoring and control. If the temperature deviates from the desired range, alerts can be sent to operators or automated systems to take corrective action.

Automation and Control Systems

Innovative TCS in the food industry often relies on advanced automation and control systems. These systems use digital technology to regulate temperature, humidity, and other environmental factors within food storage facilities, refrigerated trucks, and processing plants.

Mobile Apps

Food industry professionals can use mobile apps to monitor and control TCS remotely. They can check temperature readings, receive alerts, and adjust settings from their smartphones or tablets, providing convenience and efficiency.

RFID and NFC

Radio-frequency identification (RFID) and near-field communication (NFC) technologies are used to track individual food items or packaging containers. They can store temperature data and provide real-time information about a product’s temperature history, helping to ensure food safety.

Cloud-Based Solutions

Cloud computing allows for centralized storage and analysis of temperature data. This enables multiple stakeholders in the food supply chain to access and share information securely, making it easier to maintain temperature control standards.

Data Analytics

Data analytics and machine learning algorithms can process vast amounts of data generated by temperature sensors. This data analysis can provide insights into temperature trends, potential issues, and predictive maintenance to predict equipment failures before they occur, reducing downtime and preventing temperature control issues.

In the world of food safety and quality assurance, maintaining the ideal time-temperature environment for food products is paramount. For ages, this task depended heavily on manual monitoring and paper-based record-keeping systems. However, the advent of technology has paved the way to a different outlook for controlling the time-temperature environment of food. As the food industry continues to evolve, embracing technology-driven solutions is a smart choice and a critical step toward ensuring the safety and quality of the products we consume.

Smart Record is a digital record-keeping software solution that can take care of the heavy lifting, automating the creation process of digital monitoring forms tailored to your specific daily food safety procedures. It streamlines and elevates the process of converting all food safety records into digital files securely stored in the cloud for enhancing food safety efforts by sending intuitive notifications to food handlers to remind them of upcoming tasks, creating an intuitive dashboard for a one-stop solution to food safety operation status, and ensuring that time-temperature monitoring for TCS foods is consistently performed on schedules.

Smart Integration is another state-of-the-art digital solution for integrating aspects of different software modules of Smart Food Safe and connecting them with internal or external systems, such as other software or hardware products. By doing so, Smart Integration becomes a game-changer in automating the monitoring efforts necessary for safeguarding foods from time-temperature abuse by enabling the integration of surveillance and control devices or instruments with digital monitoring systems such as Smart EMP, Smart Record, and many more through technologies such as Bluetooth, Wi-Fi, Sensors, or Gateway.

Smart Record also combines the following integration features:

Voice Integration – Smart Record includes voice integration, which enables users to supervise the handling of digital records through voice commands effortlessly, eliminating the need for manual data entry.

Bluetooth Integration – Smart Record also permits the integration with Bluetooth technology, allowing for the automatic capture of data from paired devices, sensors, or beacons.

IoT Integration – Integration with IoT-enabled devices through APIs ensures data accuracy, streamlines record management processes and provides real-time insights to support informed decision-making.

Device Library – Our expanding suite of manufacturers and devices enables users to integrate their own devices that they currently use with Smart Record, ensuring a customized experience.

_1.png)